Medical Device Prototyping

SOFTWARE DESIGN

Software is everywhere. We can not do without it anymore. But software can also have a huge impact on project costs and timeframes.

The multi-disciplinary approach of our team helps to minimise misunderstandings and optimise the possibilities within your project.

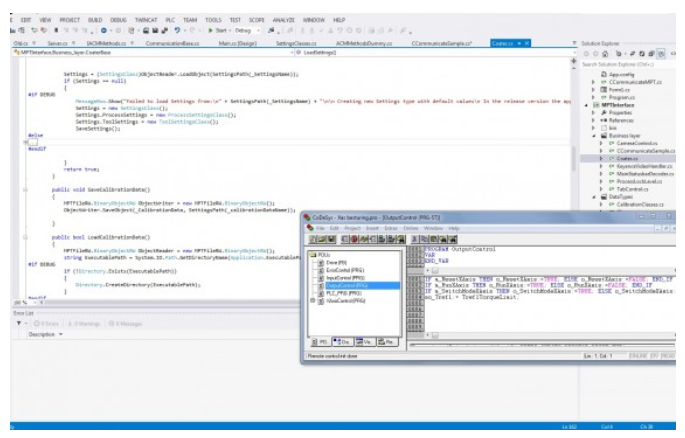

Not only do we write all code for PC’s or PLC’s in house, but we have developed our own software structures that are used throughout our various projects – reusing modules, minimising risks, minimising time investments and maximising results.

The Graphical User Interfaces (GUI) developed by us are easy to understand and use. The clean and clear design is intuitive.

Our “Out of the Box” design philosophy has recently resulted in the development of the Flexible Program Interface.

This is a completely new and unique way of programming the process cycles for balloon forming. The FPI was firstly introduced with the BFM-500-S machine and immediately customers loved it. The FPI gives possibilities and insights non existing in any other balloon forming machine currently at the market.

The FPI has now also been implemented on tge CR-240-FSCP. This Flexible Stent Crimping Platform is an ideal base for to develop and design new stents

SOFTWARE VALIDATION SUPPORT

With software comes software validation.

You need to validate any final solution before implementing it in your production, and we can assist with this process. As we designed and wrote the software we understand the test requirements of it. We can draw up a report containing the specifications and requirements. We will then determine what is required to test and proof this, and design specific test protocols.

We can help you with pre-validation testing , or optionally we execute the tests. We can provide guidelines on how to tackle the often cumbersome process of the validation of software.

This optional additional validation support can help you shorten your implementation time and thus have your production up and running earlier. That is val